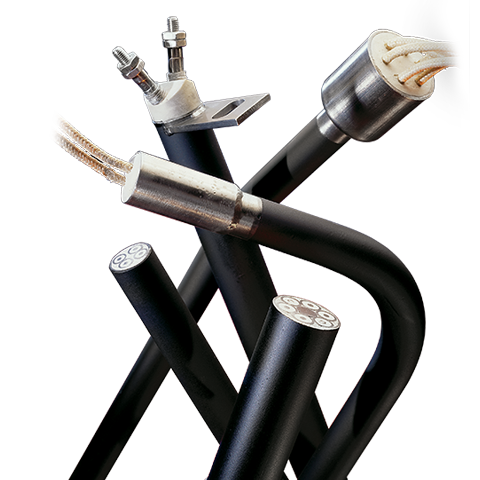

CARTRIDGE INSERTION HEATERS

Watlow designed and manufactured the first swaged cartridge heater and revolutionized the heating element industry.

With premium materials and tight manufacturing controls, Watlow's cartridge heaters (insertion heaters) provide superior heat transfer, uniform temperatures, resistance to oxidation and corrosion and long life even at high temperatures.

Cartridge heaters are an excellent choice to use as a conductive source for heating solid metal plates, blocks and dies or as a convective heat source for use in a variety of liquids and gases. Cartridge heaters can be used in a vacuum atmosphere with proper design guidelines.

TUBULAR HEATERS

Tubular heaters are used for practically the entire range of electric resistance heating applications.The wire is centered in a metal sheath and insulated with high quality magnesium oxide which is highly compacted around it and acts as an electrical insulator

Single- and double-ended tubular heaters lend themselves to virtually the entire range of immersion and air heating applications. They have a variety of mounting and termination options that make them ideal for industrial applications. Watlow® tubular heaters are UL® and CSA component recognized up to 240V.

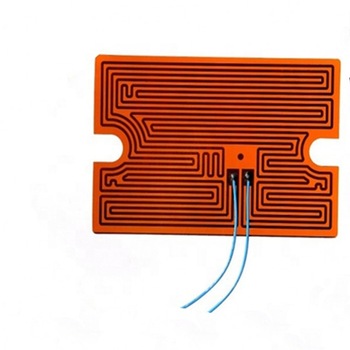

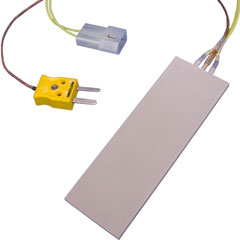

FLEXIBLE HEATERS

Flexible heaters from Watlow are thin, bendable and shaped to fit almost any type of equipment. Heat can be applied to the most complex shapes, geometries, curves and pipes conceivable without sacrificing efficiency or dependability..

A flexible heater is a chemically etched, screen printed, or wire wound heater which can be flexed or bent to conform to the contours of the surface which requires heating. There are many types of flexible heaters, including silicone rubber heaters (both etched and wire wound), Polyimide/Kapton® Film heaters, carbon printed heaters, and transparent heaters

IMMERSION HEATERS

Immersion heaters are used to heat many liquid substances like water, oil, chemicals and even to stabilize gas within their tanks. They are used in many industries within different liquid storing tanks, during the processing of pipes and in pressurizing the storing containers.

Watlow's immersion heaters are designed primarily for direct immersion in liquids such as water, oils, solvents and process solutions, molten materials as well as air and gases. By generating all the heat within the liquid or process, these heaters are virtually 100 percent energy efficient.

FLUID DELIVERY HEATERS

Watlow's heated syringe provides a heated fluid and drug delivery solution that maximizes patient comfort while reducing risk. The versatile Watlow heated syringe system produces consistent results by reducing temperature and viscosity variations.

Watlow's syringe heater was developed for the needs of medical injection applications. The special design provides a heated fluid and drug delivery system solution with long operational life which improves system reliability while reducing equipment down time.

CIRCULARATION HEATERS

Watlow's circulation heaters are compact heating systems for fluids and gases. These heaters are ideal for applications such as purified and inert gases, supercritical fluids and liquids like de-ionized water for use in semiconductor and electronics industries as well as for general liquid and gas heating applications.

A Circulation heater is a heating unit securely mounted inside a thermally insulated tank. The heater unit is either a flanged or a screw-plug immersion heater and it sits inside a pressure vessel or the body of a pipe.

AIR HEATERS

Watlow has developed a line of process air heaters that offer performance and versatility in medium to low temperature applications. This rugged and reliable line of industrial heaters efficiently conducts heat.

It is a device that transfers heat from a source to the air. This requires a fan and usually a heat exchanger of some form. Electric heat is direct and transfers heat directly from the resistance wires and to the air through a fan attached behind it.ir from your home blows across the heat exchanger to be warmed. It is then blown through a system of ducts to distribute around your home. During warm seasons your heating system works with your central air conditioning.

HIGH-TEMPERATUREHEATERS

A heating element is used to convert electricity into heat, and within an industrial furnace, there are various materials that can be used. Typically, iron-chrome aluminum or nickel chrome alloys are used in furnaces, and the standard shapes are cylindrical, semi-circular, or flat panels. This blog post will look at the other different types of materials that can be used as high temperature heating elements.

Watlow leads the industry in developing high-temperature heating technologies and products in various sizes and constructions to fit a broad range of processes and applications. tubular and ceramic fiber heaters offer capabilities such as ultra-fast ramp rates, precise temperature uniformity and high temperatures for applications requiring low thermal mass. Heaters are sized and designed to accommodate small to large applications and various environmental conditions.

SPECIALTY HEATERS

Watlow specialty heaters are designed for thermal applications where high performance is required, and fast response and uniformity are essential.

Specialty heaters from Watlow have design flexibility to meet different applications requiring different construction methods. This flexibility allows the heaters to be configured in a variety of shapes and sizes depending on the application.

STRIP/CLAMP-ON HEATERS

Watlow's strip/clamp-on heaters are a versatile solution for a number of applications. They can be bolted or clamped to a solid surface for freeze and moisture protection, food warming and other applications. These heaters make use of the most advanced heat construction techniques.

Strip heaters are used principally for convection-type air heating and clamp-on installations. When selecting strip heaters for either, two important factors must be considered: The proper sheath material for resisting any rusting and oxidizing inherent in the process or environment and for withstanding the sheath temperature required.

BAND/BAZZEL HEATERS

Watlow's line of band/barrel heaters are available for fast delivery and can be easily installed into original equipment manufacturer (OEM) and end user applications. This variety of heaters allows the user to specify the construction needed to result in the best heat solution.

The band heater's performance and name are derived from Watlow's exclusive mineral insulation—a material with much higher thermal conductivity than mica and hard ceramic insulators used in conventional heaters.

NOZZLE HEATERS

Nozzle Heaters has a unique set of capabilities, each nozzle heater is designed to meet specific application requirements. Whether an application requires high performance, high temperature or high watt density Watlow has the heater to fit the application.

RADIANT HEATERS

Radiant heating systems supply heat directly to the floor or to panels in the wall or ceiling of a house. The systems depend largely on radiant heat transfer -- the delivery of heat directly from the hot surface to the people and objects in the room via infrared radiation.

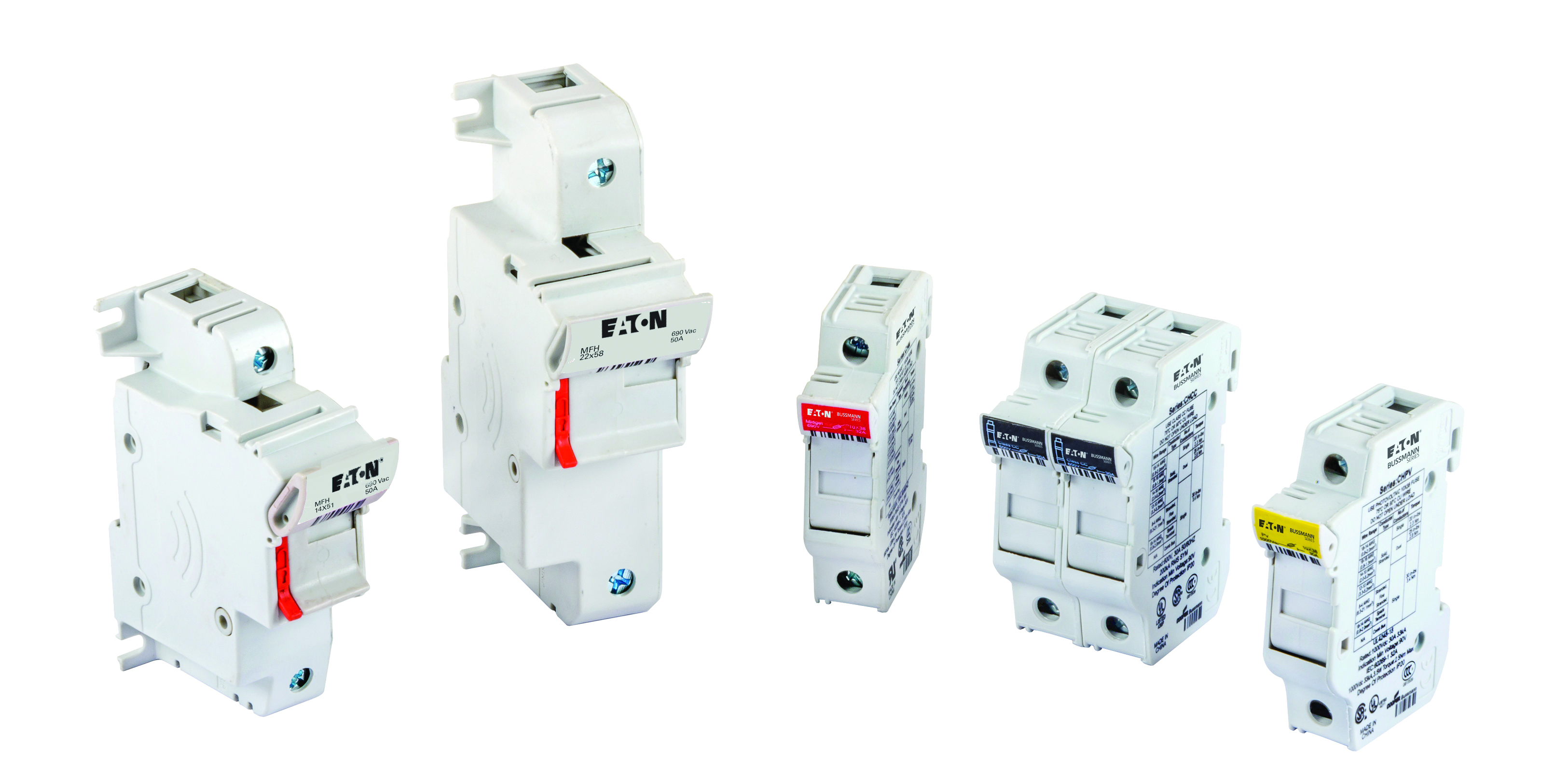

THERMOSTATS AND ACCESOREIS

Watlow designs and manufactures all of the components of a thermal system. This allows Watlow to recommend, develop and deliver the optimal thermal solution of customer's equipment.